Selamat Datang Bahagian Mekanikal Mid-West !

MWMECH

MWMP-192001

ya

| Status ketersediaan: | |

|---|---|

| Kuantiti: | |

|

| |

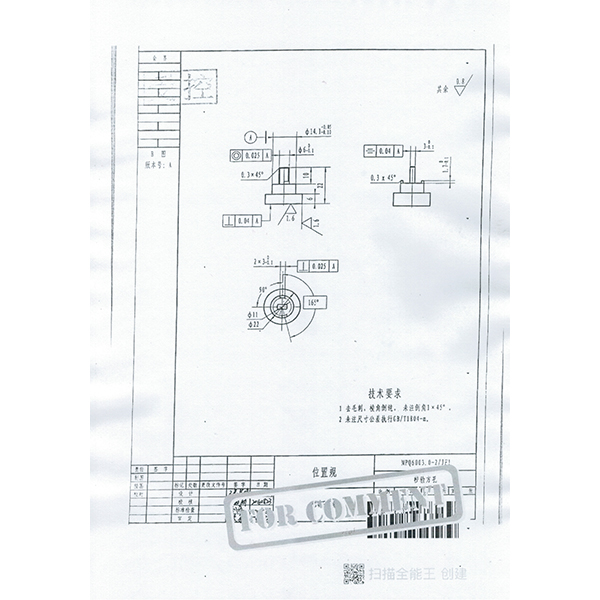

These pictures and drawings are our customized products. It shows our supply ability. Due to the Intellectual Property, it's only for reference.

Assemble line work fixture& tooling devices and components are the key back up for the factory automation processing.

Inspection and test tooling products are assemble line tools for testing and inspecting the positions, directions, hight, depth or space capacity of the parts or equipment to assure the correct result of the previous step and make perfect preparation for next work step. We can produce similar parts according to your drawings.

Various of metal materials with different surface treatments are adopted to satisfy with your requirements and keep efficient running of your production line. Since the work fixture tooling and parts are closely connected with the practical production scenes and conditions, we produce customer orientated and non-standard OEM products.

You need to provide clear drawings and requirements so as to for our engineers understand thoroughly. Our regular service

scope as following but not limited, up to your drawings:

Assemble Line Work Fixture and Tooling,

Altimetric Survey Mechanism Tooling,

Height Detection Mechanism Tooling,

Inspection Assemble Line Work Fixture and Tooling,

Cutting Assemble Line Work Fixture and Tooling,

Testing Assemble Line Work Fixture and Tooling,

Measuring Assemble Line Work Fixture and Tooling...

Non-Standard Mechanical Parts for Assemble Line,

Assemble Line Punch,

Assemble Line Head Punch,

Assemble Line Connecting -Adapter Parts,

Assemble Line Mounting Plate Components,

Assemble Line Metal Gripper,

Assemble Line Guide Sleeves,

Assemble Line Orientation Inserts,

Assemble Line Flange Connector parts,

Assemble Line Device,

Orientation Parts for Assemble Line,

Measurement Parts for Assemble Line,

Non-Standard Inspection Parts,

Non- Standard Cutters for Assemble Line...

Good consistency, stable quality, precision tolerances +/-0.002mm to +/-0.005mm.

Almost zero repair rate and zero defective products, all replacement or repair for free due to our fault within 1 year warranty period.

Quality control assurance.

Fast after-sale respond.

Inner: bubble bag, PE bag or plastic seal with anticorrosive oil plus outer carton box, or other safe package.

You may have many choices of surface treatments according to your needs. Below are some susual methods we use.

FAQ

Q: What service can you do?

A: OEM/ODM. Free samples available after price confirmed, but you need to share the sample freight. We produce the parts per customers'drawing or sample. Concerning the protection of customers'intellectual property, we don't sell our customers'same product to the third party.

Q: What data should the customer provide for a precise quotation?

A: The drawings or samples, quantity, tolerance, standard, material, surface finish, other special requirements, etc.

Q: What're your delivery methods?

A: DHL, EMS, UPS, land transport or sea freight available.

Q: How do you assure the quality control?

A: Full inspection with test report and material composition certificate for each order and 1-year after-sale service for free repair or replacement for deficit products. Almost zero repair rate and defective products all replacement or repair for free.

Q: How long is your lead time?

A: 10-30days up to the quantity.

Q: what surface treatments can you deal with?

A: Titanium nitride (TiN), TiCN, titanium plating, blackening, carburize, zinc plating, zinc coating, galvanization, chrome plate, etc.

Q: what's your payment term?

A: T/T, L/C, western Union, PayPal, etc.

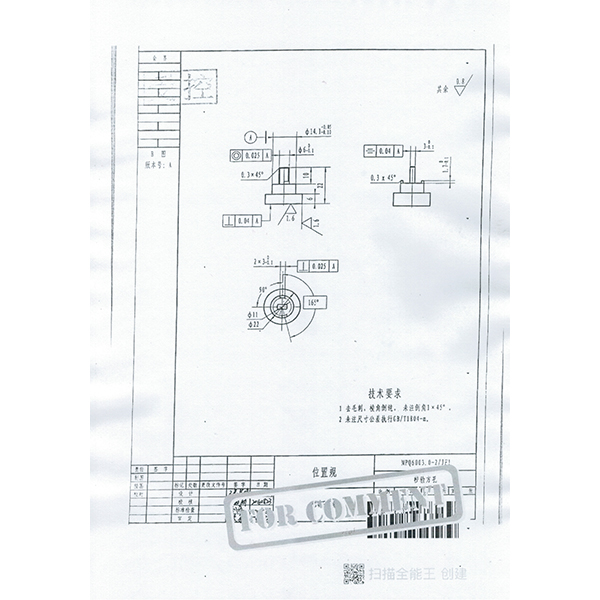

These pictures and drawings are our customized products. It shows our supply ability. Due to the Intellectual Property, it's only for reference.

Assemble line work fixture& tooling devices and components are the key back up for the factory automation processing.

Inspection and test tooling products are assemble line tools for testing and inspecting the positions, directions, hight, depth or space capacity of the parts or equipment to assure the correct result of the previous step and make perfect preparation for next work step. We can produce similar parts according to your drawings.

Various of metal materials with different surface treatments are adopted to satisfy with your requirements and keep efficient running of your production line. Since the work fixture tooling and parts are closely connected with the practical production scenes and conditions, we produce customer orientated and non-standard OEM products.

You need to provide clear drawings and requirements so as to for our engineers understand thoroughly. Our regular service

scope as following but not limited, up to your drawings:

Assemble Line Work Fixture and Tooling,

Altimetric Survey Mechanism Tooling,

Height Detection Mechanism Tooling,

Inspection Assemble Line Work Fixture and Tooling,

Cutting Assemble Line Work Fixture and Tooling,

Testing Assemble Line Work Fixture and Tooling,

Measuring Assemble Line Work Fixture and Tooling...

Non-Standard Mechanical Parts for Assemble Line,

Assemble Line Punch,

Assemble Line Head Punch,

Assemble Line Connecting -Adapter Parts,

Assemble Line Mounting Plate Components,

Assemble Line Metal Gripper,

Assemble Line Guide Sleeves,

Assemble Line Orientation Inserts,

Assemble Line Flange Connector parts,

Assemble Line Device,

Orientation Parts for Assemble Line,

Measurement Parts for Assemble Line,

Non-Standard Inspection Parts,

Non- Standard Cutters for Assemble Line...

Good consistency, stable quality, precision tolerances +/-0.002mm to +/-0.005mm.

Almost zero repair rate and zero defective products, all replacement or repair for free due to our fault within 1 year warranty period.

Quality control assurance.

Fast after-sale respond.

Inner: bubble bag, PE bag or plastic seal with anticorrosive oil plus outer carton box, or other safe package.

You may have many choices of surface treatments according to your needs. Below are some susual methods we use.

FAQ

Q: What service can you do?

A: OEM/ODM. Free samples available after price confirmed, but you need to share the sample freight. We produce the parts per customers'drawing or sample. Concerning the protection of customers'intellectual property, we don't sell our customers'same product to the third party.

Q: What data should the customer provide for a precise quotation?

A: The drawings or samples, quantity, tolerance, standard, material, surface finish, other special requirements, etc.

Q: What're your delivery methods?

A: DHL, EMS, UPS, land transport or sea freight available.

Q: How do you assure the quality control?

A: Full inspection with test report and material composition certificate for each order and 1-year after-sale service for free repair or replacement for deficit products. Almost zero repair rate and defective products all replacement or repair for free.

Q: How long is your lead time?

A: 10-30days up to the quantity.

Q: what surface treatments can you deal with?

A: Titanium nitride (TiN), TiCN, titanium plating, blackening, carburize, zinc plating, zinc coating, galvanization, chrome plate, etc.

Q: what's your payment term?

A: T/T, L/C, western Union, PayPal, etc.

Tambah.: No.1518, F15, Bangunan 1, Pusat Kewangan Qianhai Life, Jinqiao 3rd Road 418#, Daerah Ekologi Chanba, Xi'an, Shaanxi, China.